Week 17: Applications and Implications

What will it do?

I am designing, making and programming a chair which will talk to a person that has sat on it.

Original thoughts were that it would be a 'rude' chair that would speak racist and otherwise politically incorrect comments to the person sitting on it. Ideally I would like it to speak out the politically incorrect phrases that politicians have said (and continue to say) acting as a comment towards those who seem to be oblivious of the world they live in and the positions they hold. Some research that I did in locating such phrases proved that it would be very difficult and time consuming to collect, although I know that they exist.

So for now I will start small. I am also in need of some positiveness instead of rudeness at this moment, so I will make it speak the words of a dear auntie I had. She would mumble some words (in Greek) every time she sat down, about how good it was to be… sitting down! I will record my voice saying her words, because I am a descendant of hers.

In the future I may take it to the next level, after I have had the time to collect the politician's phrases, since I have always made comments in my work about their role in the society.

Who's done what beforehand?

Sensors have been widely used in art for quite some time. I believe that this project is more about humour and giving people a smile on their face, rather than the introduction of a big new idea or invention. I have always enjoyed pieces of work that can put a smile on my face as well as interactive works in contrast to the kind which exhibition visitors are not allowed to touch. I have been lucky enough to see this reaction triggered in people by my products and I want to continue to do this through the new skills that I have aquired. Here is a project done in Bristol about striking up conversations with the city's lamp posts, post boxes and other street furniture.

CNC-made chairs and other furniture have been around for quite some time. With the growth of the FabLab network as well as the internet, they are becoming increasingly popular. Many plans can be found in websites such as 'Instructables'. Some interesting examples can be found below.

What materials and components will be required?/ What parts and systems will be made?

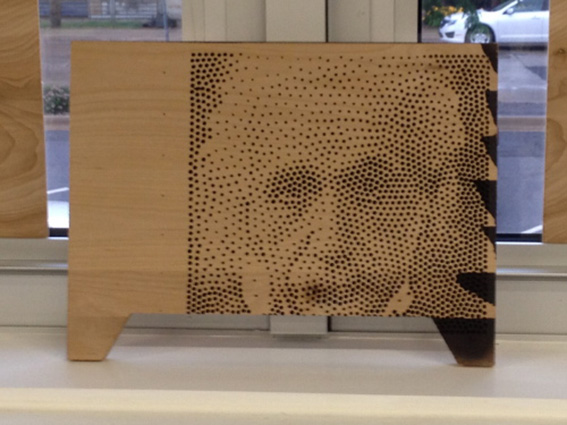

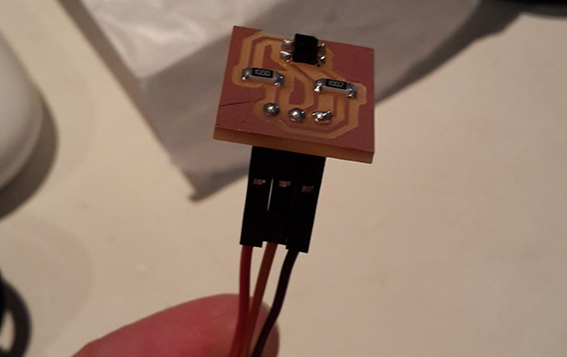

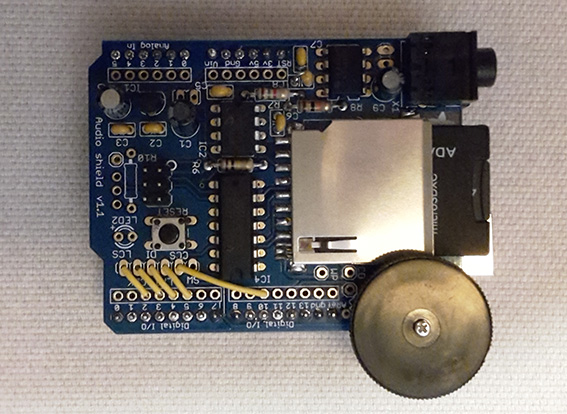

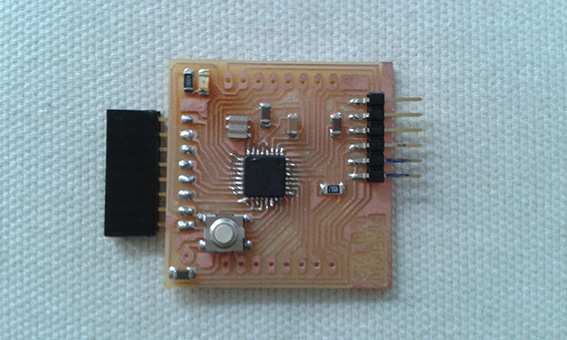

For the actual chair, I will be using 8mm plywood and the plan is to make the whole chair out of a 122cm x 250cm piece. I have also purchaced an Adafruit sound shield, together with an SD card and speaker. I will be using the sensor I made for my input devices week. I will then connect the shield to my FabKit and a simple LED board which will act as an output device.

Where will they come from?

The plywood will be purchaced from a local distributor here in Amsterdam. The rest of the components are easily accessible in the FabAcademy inventory :-) but they are mostly purchaced from Farnell in Europe or Digikey in the US. Of course, there are many more suppliers like Kiwi Electronics, Sparkfun, RadioShack etc. Radio Rotor is a good local supplier here in Amsterdam.

How much will it cost?

After going throught the Farnell website I understand that the components I will need to use would not cost more than 10 - 15 Euros. I have one AVR ATtiny 328 on my FabKit and several capacitors, regulators and resonators. Some leds, switches etc, if I count all boards together. Their prices range from 0,01 Euros to 3,00 Euros. I have already bought the Shield and Sound pack for around 40 Euros. The whole project is in the range of 80 Euros including the 8mm Birch Plywood. I would say 100 Euros in total for any unpredictable expences.

What processes will be used?

I will be using Rhino to design my chair in 2-D and 3-D and I will then export and cut it on the ShopBot. I am not sure yet if it will require 2 or 3 axis machining. I will definitely be using Eagle to design my LED output board and the modela to mill it, as well as the soldering station for stuffing the boards.

What questions need to be answered?/ What tasks need to be completed?

- Recording my voice and getting it to play from the SD card.

- How do I migrate from the Arduino board to the FabKit?

- What kind of code do I need to write to make the infrared sensor act as a trigger for the speech and LED?

- What kind of board do I need to make for the LED?

- Where and how deep into the chair do I need to place the infrared sensor?

- How will all these components be fixed on the chair?

- How will it be powered?

- How should the speaker connect to the shield/fabkit

- How can they be hidden, but at the same time within reach for debugging?

- What will be the final shape of the chair? Ideally it will have the ability to be flatpacked.

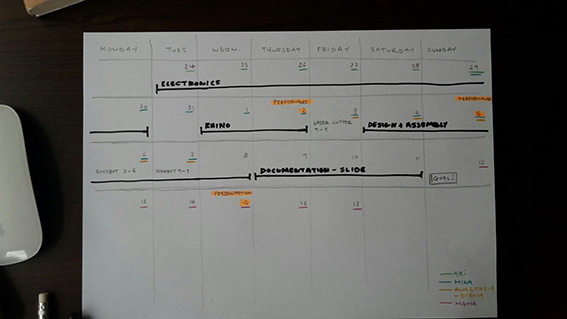

What is the schedule?

The schedule is somewhat ambitious! I would like to be able to finish the final project a couple of days before the presentation date, which for us is the 15th of June. This is because I would have time to tackle any issues that may arise in the process and be a little more comfortable with completing my documentation, although I am already recording it as I go along. The ambitious plan is shown in the picture above (together with the dates of when our visitors are coming to Amsterdam and my partner's MA graduation performances!). Ideally I would like to have all electronics finished and working by the 2nd of June. Since compiling that schedule I realized that I prefer to be working on the electronics during the week when I have Emma's support and on the design of the chair and documentation over the weekends, because I am more comfortable working alone on those areas. I also feel quite comfortable with the use of the laser-cutter and the ShopBot. So the main plan, is to finish the electronics part as soon as possible and concentrate on the rest afterwards. I have already booked the machines for modelling and the full size cut on the 3rd, 6th and 7th of June. If it all goes well, it will be a matter of putting it all together after that date. Hopefully the hardware will all be completed by the 12th of June and I will only need to compile the slide in adittion to final touches to the documentation.

How will it be evaluated?

For the evaluation of the project, I will implement a SWOT Analysis that I have lately found useful in order to evaluate my projects. It is about identifying the Strengths, Weaknesses, Opportunities and Threats of a specific project, product, business plan etc and can really be applied to any situation.

Applications and Implications Lecture Back to Weekly Assignments Home